How to Eco Product Design

We decided to use Polypropylene (PP) for the coloured parts with an ultraviolet additive to stop the colour fading in the sun. Polycarbonate (PC) was used for the clear parts because it’s optically clear, durable, scratch resistant and hard wearing. Although PP and PC can be recycled, they are usually incinerated or go to landfill because the local council does not collect hard plastics for recycling. Mixed waste is supposed to be sorted and plastics recycled if economical, but I assume this rarely happens.

The sketches shown above were approved by the client and then we develop the idea in CAD.

The factory that moulded the parts was next door to our client, so the transport footprint was low. The cost to manufacture in the UK was lower than China if the automated moulding machine was run for 24 hours to produce five thousand sets of parts in one run.

The transparent plastic body was made in two halves joined together by ultrasonic welding. No screws or chemicals were needed. The wall sections were kept thin while still maintaining their strength. It is easy and intuitive to fill the birdfeeder with seeds and hang up on a hook or branch.

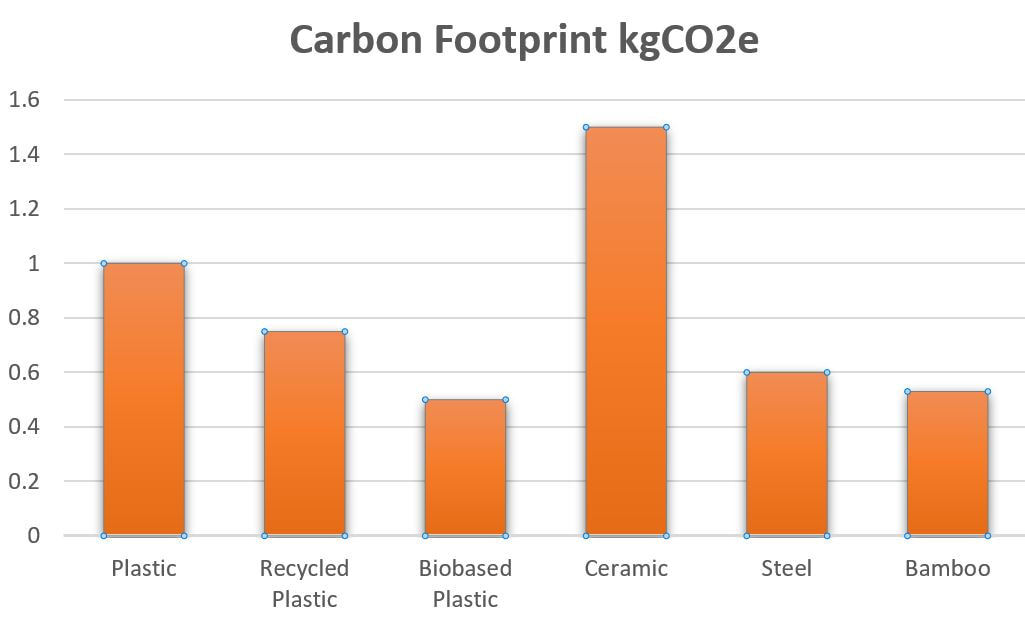

By using a free emission factor database at carbonfootprint.com we found that Polypropylene creates 4.4kg of CO2e per kg of plastic injection mouldings. We duplicated this by the weight of PP used per bird feeder. 4.4 x 0.07 = 0.3kg CO2e

We also found that Polycarbonate was 7.6 kg or CO2e per kg of plastic injection mouldings. We duplicated this by the weight of PC in each bird feeder. 7.6 x 0.18 = 1.37kgCO2e

The total CO2e emissions per feeder was 1.67kg CO2e. This doesn’t include the packaging and transport emissions, and end of life emmisions.

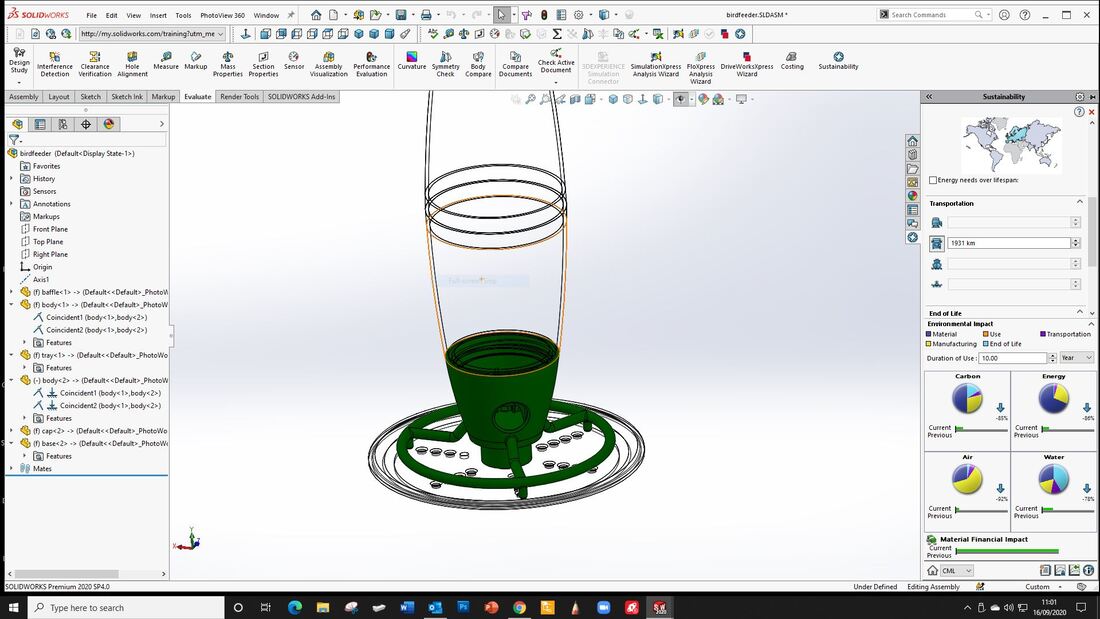

A CAD programme called SolidWorks has a Life Cycle Assessment feature called Solidworks Sustainability.

We imported the parts into Solidworks to evaluate the carbon footprint of the assembly more accurately. We choose the material and production method from the database. We selected Polypropylene for the coloured parts. We selected Acrylic (PMMA) instead of Polycarbonate for the clear body because it had a lower carbon footprint. It was optically clear, hardwearing and recyclable. We selected the region of the world where the parts would be made and sold. We specified the type of transport used and life expectancy of the product. We specified the end off life disposal; landfill, incineration or recycling. The sustainability calculator estimated a total of 1 kg CO2e would be emitted per bird feeder. This was lower than our rough estimate above.

The non renewable energy used would be 18MJ. The amount of air acidification which makes acid rain would be 0.0032 kg SO2e. The amount of water eutrophication (damaging nutrients added to water) would be 0.0004kg PO4e.

This Life Cycle assessment was then saved as a benchmark so we could modify the dimensions, materials and manufacturing methods to see if we could reduce the environmental damage.

Solidworks Sustainability can also estimate the environmental impact of electronic circuit boards. Just select circuit board as a part material. It can also calculate the impact of energy used to wash the birdfeeder with warm water each month; although we didn’t do this.

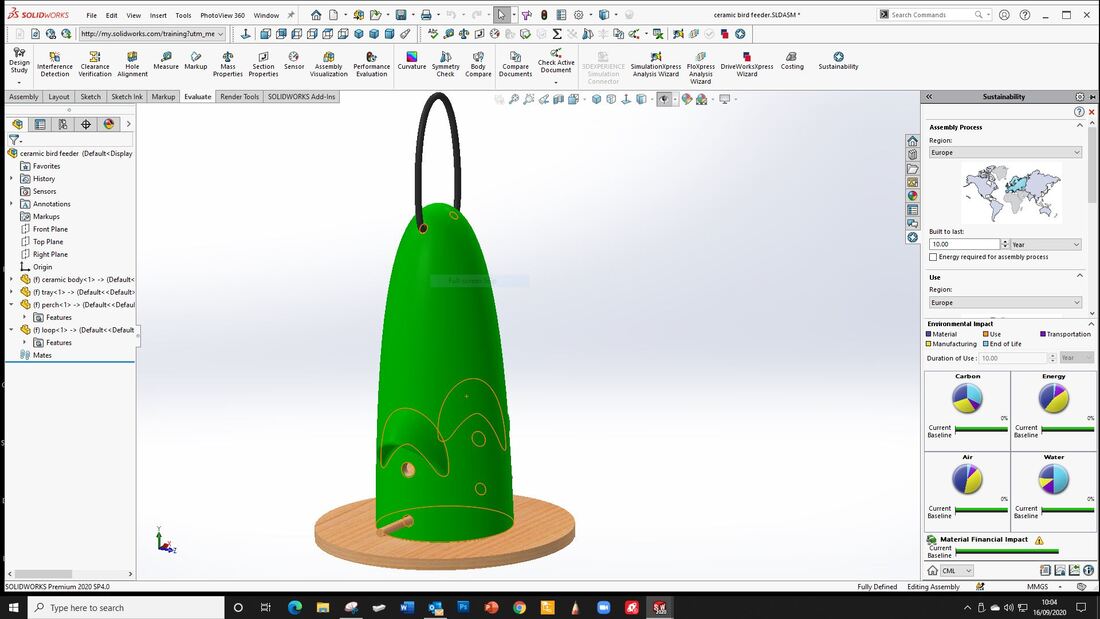

We use Sketchbook Pro to sketch up our ideas. Sketchbook Pro costs less than £20. It’s a pleasure to use and makes your sketches look great. You’ll need a stylus pen and drawing monitor like a Cintiq, connected to your PC or Mac. Once you have created a side view sketch you can import this on a plane within a 3D CAD package to help build a 3D model with the right visual proportions.

We imported the sketch into Solidworks and made a 3D CAD model so we could run the Solidworks Sustainability life cycle assessment to see if it was better or worse for the environment.

The sustainability calculator estimated a total of 1.3 kg CO2e would be emitted per ceramic bird feeder. Surprisingly this was higher than the plastic bird feeder made from petroleum based plastics.

The non renewable energy used would be lower at 12MJ. The amount of air acidification which makes acid rain would be more at 0.0058 kg So2e. The amount of water eutrophication (damaging nutrients added to water) would be more at 0.0008 kg PO4e.

We then CAD model a metal bird feeder to see how that would compare.

The sustainability calculator estimated the painted steel bird feeder would cause 0.6 kg CO2e; about half of the plastic bird feeder.

The non renewable energy used would be lower at 7.5MJ. The amount air acidification would be much less at 0.0015 kg So2e. The amount of water eutrophication would be a lot less at 0.00026 kg PO4e.

Finally we made a CAD model of an wooden bird feeder.

The sustainability calculator estimated the bambo bird feeder would cause 0.53 kg CO2e; less than all the other designs.

The non renewable energy used would be lower at 4.3MJ. The amount air acidification would be 000.51 kg So2e. The amount of water eutrophication would be 0.00034 kg PO4e.

We wanted to see if using recycled plastic would be a better option but the Solidworks sustainability database didn’t have recycled Polypropylene or recycled acrylic in the database so we had to estimate these. Companies claim that over 50% of CO2e emissions can be reduced by using 100% recycled plastic.

100% recycled PET is available could replace the acrylic body and tray. 100% recycled black Polypropylene is also available but we needed green so couldn’t use that option. By using recycled PET for the clear body and tray we estimate it would save about 25% CO2e per bird feeder.

Another option is to use Bio Based polypropylene made from organic matter. The bioplastics calculator on the Natureworks website estimated a 60% reduction of CO2e when using Biobased plastics like PP and PC.

The plastic bird feeder made from bio-based plastics had the lowest CO2e emissions.

The plastic design has a clear body so we can see when it’s empty and needs cleaning. It’s easy to refill and is more hygienic when washed. If the bird feeder is washed in warm water regularly this would also add to CO2e emissions over, its 10-year life. In the instructions we should recommend washing in cold water.

There is a free LCA program called open LCA and material databases available, but they are difficult to use. If a client wants a more bespoke LCA then they would need to ask a professional LCA consultant for help.

Enchain – Mobius is an easy-to-use professional Life Cycle Assessment (LCA) programme that has a built-in material database. You add the weights or volumes of the materials instead of importing the 3D model. It allows you to select the specific country, or town for the location of the raw materials, processing, assembly, warehouse, retail. It has a bigger database although it doesn’t allow you to choose the percentage of recycled content of plastics. View the Echochain website for more information.

Large companies are required to conduct LCAs to comply with the EU Corporate Sustainability Reporting Directive.

Is a bird feeder a useful product to have during a climate emergency? Many birds would die without the help of bird feeders because their natural habitat has been reduced in cities. People love watching the birds feeding which is good. Sunflowers are farmed to make bird feed which uses land that could be used instead for growing food. Ideally planting bushes and trees with berries on and leaving plant heads on over winter help birds feed naturally without the need for birdfeeders.

In a climate emergency we want to reduce CO2e emissions ASAP. Consumers should live within their personal carbon allowance of less than 9.3 tons per year during 2023. If they can buy and maintain a birdfeeder within their allowance then this is OK in my opinion.