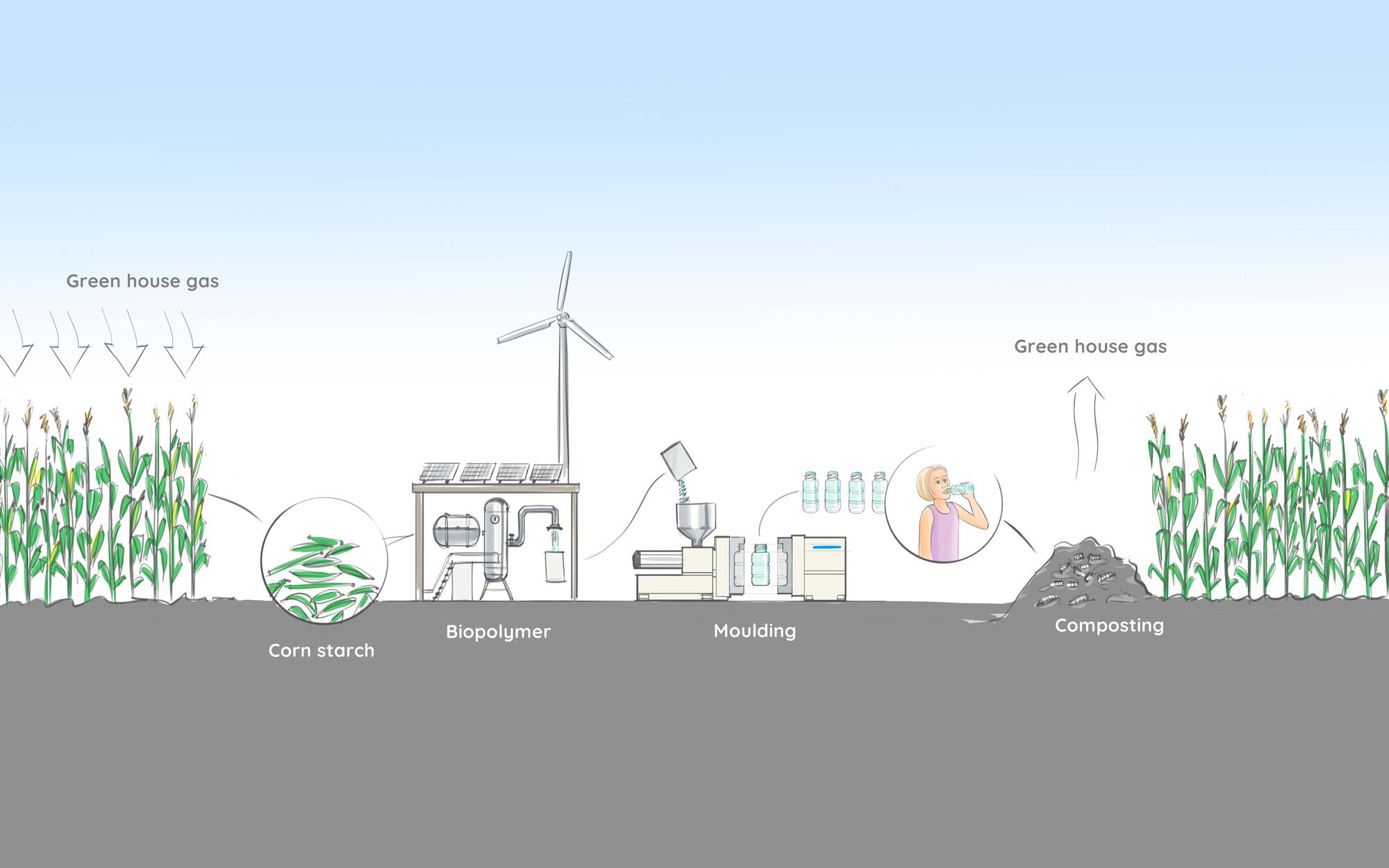

Bioplastics are made from renewable raw materials like sweet corn leaves, potatoes, wood, vegetable oil, sugar and seaweed. They have a low carbon footprint because the plants have absorbed carbon dioxide while growing.

Some bioplastics are also biodegradable so breakdown into compost. Beware some bioplastics are also be made from fossil fuel but are called Bioplastics because they are biodegradable.

Groups of bioplastics:-

Group 1. Regular plastics made from renewable raw materials.

These are regular thermoplastics like PE (polyethylene), PET (polyethylene terephthalate), PTT (Polytrimethylene terephthalate), and PA (nylon), but made from renewable biomass material rather than fossil fuels. They can also be recycled along with their identical fossil fuel-based plastics.

This is good because carbon dioxide is absorbed while growing the plant-based material and consumers can carry on putting biobased plastics in their recycling bin as normal.

Group 2. Plant-based or biobased plastics which are also biodegradable.

Some are compostable on a home compost heap, others must go in an industrial composter, others are biodegradable over a year. Vegware use a plant-based PLA plastic for their clear plastic food packs. It’s biodegradable so can be disposed of with the food waste from cafes. This is then collected and recycled in an industrial composter.

PLA (Polylaticacid) is a plant-based plastic which doesn’t have an identical fossil fuel based plastic. PLA can’t be recycled with other plastics because the existing equipment is not set up to recognise it but up to 3 percent can enter the recycling steam without harm. Improvements to the recycling facilities to accommodate PLA will happen once usage volumes of PLA increase. In the mean time it can be composted or collected and recycled separately. PLA is widely used on 3D printers and can be recycled on it’s own by shredding and melting it back into the 3D filament but this rarely happens, but could go in an industrial composter.

Group 3. Fossil fuel-based plastics that are compostable.

Regular fossil fuel based thermoplastics like PP, HDPE, LDPE, PVC, PET, can have additives to make them compostable.

They degrade with either UV light, air or water.

PBAT (polybutylene adipate terephthalate), PCL (Polycaprolactone), and bio-based polyurethanes (PUR), are made from fossil fuel but can biodegrade from a few weeks to years. Some can be composted on home compost heaps, others need an industrial composter, others will take years to decompose in a landfill. Home compostable bags must be clearly labelled to tell consumers to recycle them in their compost bin, but not to put them in their mixed plastic collection bin.

If all plastic was biodegradable then if it did end up as rubbish or in landfill it would eventually break down in to water, carbon dioxide, biomass and possibly methane. Biodegradable plastics can also be designed to break down in air, water or UV light. The Oxy-degradable plastics are not recommended because they break down into small flakes that are harmful to wildlife.

If a product is being designed for a closed loop system (were the waste plastic can easily be collected) then biodegradable plant-based plastics are a good option. Because they can be returned to a single source and recycled into compost or plastic again.

At the moment bioplastics are more expensive than regular fossil fuel based plastics. Some people justify fossil fuel-based plastics because they are made of a by-product of oil, but this is still leading to more oil extraction and greenhouse gas emissions. Bioplastics can reduce greenhouse gas emissions by over 50 percent compared to the fossil fuel oil equivalent. We need to stop extracting oil and use plant based renewable solutions to reduce climate change and satisfy the growing consumer demand for sustainable products. They cost more than petrochemical based plastics, but the cost of petrochemicals might rise. They can be made from food waste such as leaves from corn plants but in some cases they us land and water that otherwise might be used for food.

So consider use bio plastics for all your future projects. Choose what is the best option based on the end of life scenario.

If you want the item to be recycled in the existing mixed plastic bin then use regular plastics made from renewable biomass, (group 1).

If you want to compost the plastic, then use plant based plastics designed for composting but make sure they last long enough for your intended use and label them for composting only, so they don’t end up in the mixed plastics bin.

The way to make the biggest reduction to CO2e emissions is not by using bioplastics but my make sure the plastic can be reused or recycling. If this is not possible them a compostable or low CO2e bio plastic may be the next best option to reduce the CO2e footprint.

For more information visit

NatureWorks

WRAP

European-bioplastics

To find out how plastic is made watch Plastic 101 made by National Scientific and see wikiHow.